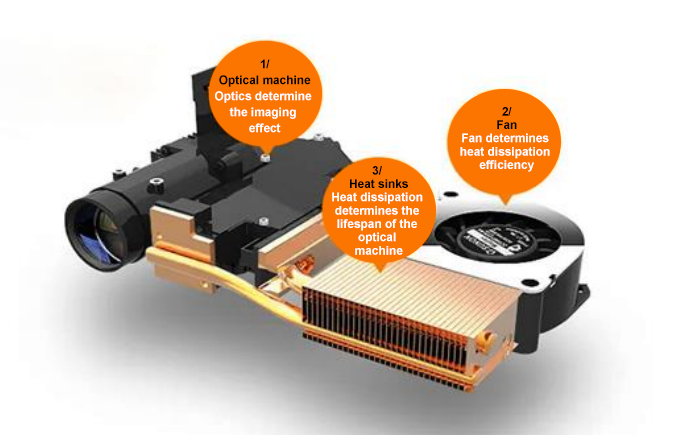

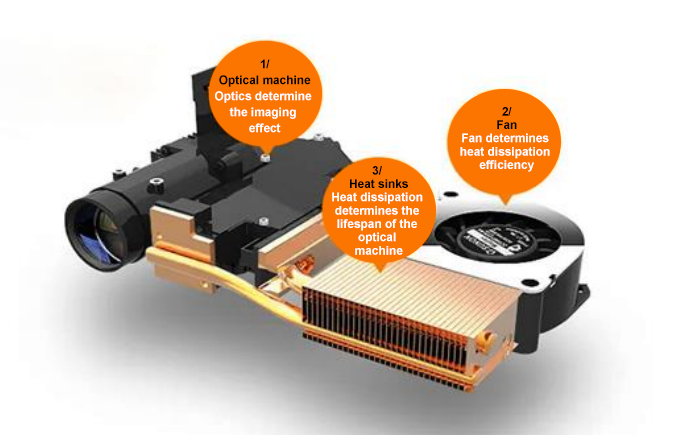

Application of Thermal Conductive Materials in Projectors

The projector is mainly composed of an optical system, electronic system, mechanical system, and cooling system. Its working principle is to convert digital data into optical signals through electronic signals, which are then projected onto the screen through the lens. The bulb inside the projector is an essential component in generating the optical signal, and the process of generating optical signals consumes a large amount of electrical energy, producing a significant amount of heat.

The projector generates a significant amount of heat during operation, primarily from components such as the internal bulb, imaging system, and power supply. To ensure stable operation and extend the lifespan of internal components, an effective cooling system is crucial. Below are the two main cooling methods used in projectors:

1.Fan Cooling

By installing a fan, the heat generated inside the projector is expelled through the exhaust vents. While this method may produce some noise, it effectively removes heat and ensures the projector operates normally. Epson projectors use this cooling method, where the heat generated by the ultra-high-pressure mercury lamp or laser light source, along with the large-size LCD display chip, is dissipated through the fan.

2. Layered Exhaust Ventilation Cooling

This is a more advanced cooling technology that strategically distributes intake and exhaust vents to create a well-organized airflow cycle inside the machine. This ensures that each heat source is effectively ventilated and cooled. This method not only reduces noise but also improves heat dissipation. Toshiba's DLP models and certain product lines from Philips adopt this technology.

3.Heat Pipe Cooling

A heat pipe is an efficient heat transfer component, and its working principle is based on the heat conduction method within heat transfer, convection, and radiation. Specifically, the heat pipe consists of a tube shell, a liquid absorption core, and end caps. The interior is evacuated to a negative pressure state and filled with an appropriate low-boiling-point liquid. This liquid has a low boiling point and easily evaporates. When one end of the heat pipe is heated, the liquid rapidly evaporates, and the resulting vapor flows to the other end under a small pressure difference, where it releases heat and re-condenses into a liquid. The liquid then returns to the evaporating end through capillary action in porous materials, forming a continuous cycle. This process occurs rapidly, enabling heat to be continuously transferred from one end of the heat pipe to the other.

4. Thermal Interface Material Cooling

The cooling principle of thermal interface materials primarily lies in filling the small gaps between the heat source and the heat sink, reducing thermal contact resistance, and improving heat dissipation performance.

In conclusion, the cooling methods of projectors are diverse, aiming to ensure stable operation of the device in various environments, while protecting internal components from the effects of high temperatures and extending its service life.

-

Previous article:LED TV

-

Next one:Washing Machine