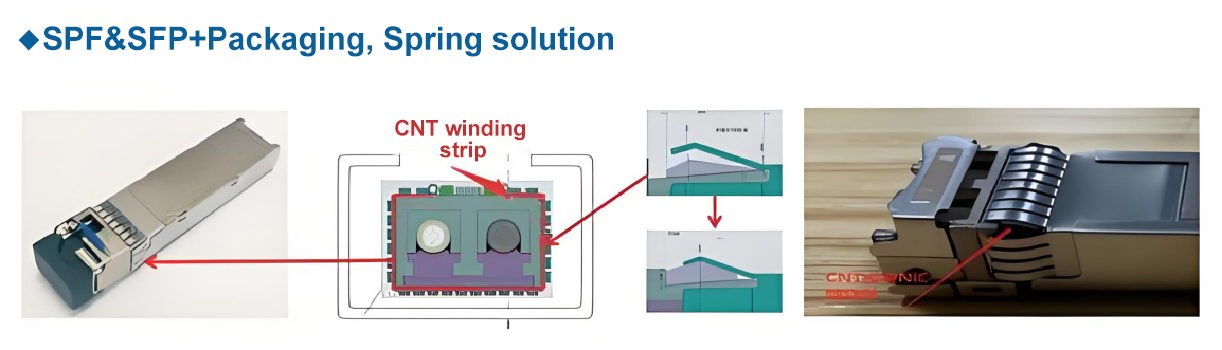

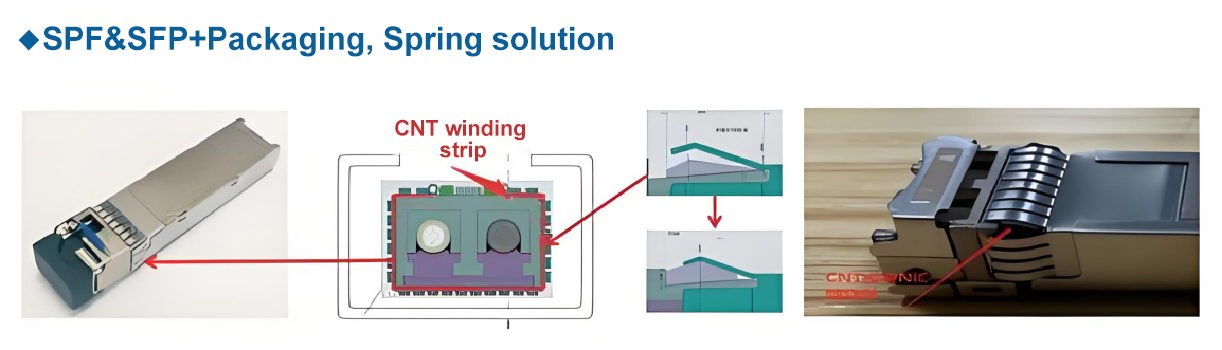

Conductive and Shielding Solutions for Optical Modules

Conductive rubber materials are made into barriers or used to wrap metal shields to address optical port leakage. Without the use of conductive rubber in rigid contact, an improvement of at least 3 dB can be achieved. When conductive rubber is used as a barrier or to wrap with fibers, it helps solve the issue of electromagnetic wave leakage from optical ports, achieving an improvement of 3-5 dB.

The wrapping strip here uses conductive rubber for wrapping, optimizing the leakage in the 30°-45° range by 3-5 dB.

-

Previous article:Communication Base Station

-

Next one:Switch