Thermal Conductive Pad

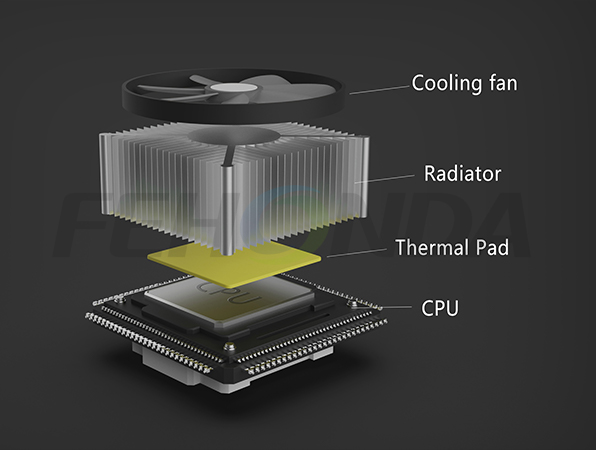

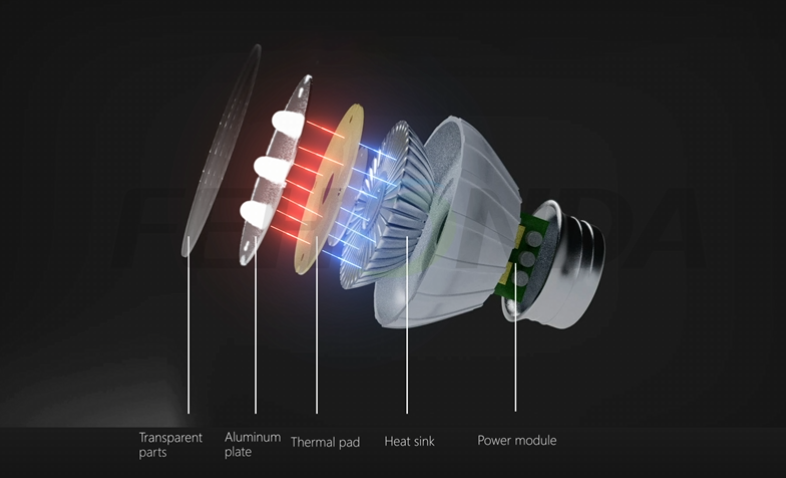

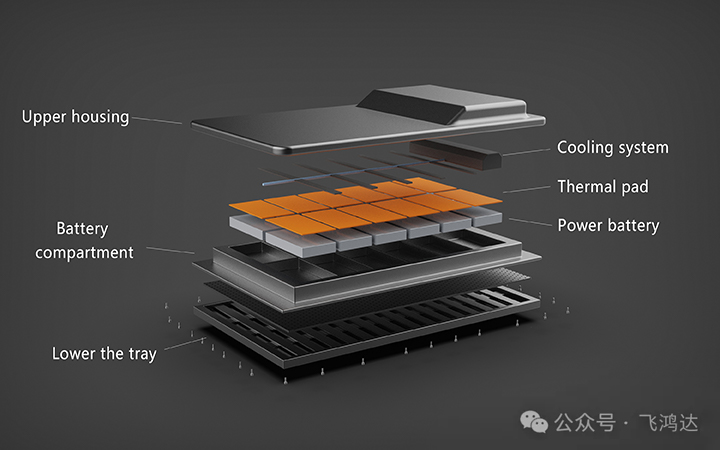

Thermal Pad have good insulation, compressibility, softness and excellent thermal conductivity. The surface is naturally sticky and can fill gaps, squeeze out the air between the heat source and the radiator to achieve full contact, complete the heat conduction between the heating part and the heat dissipation part, effectively improve the heat transfer efficiency, and at the same time play the role of insulation and shock absorption.

Thermal Pad can meet the design requirements of miniaturization and ultra-thin equipment. It is an excellent thermal conductive filling material and is widely used in various electronic component products.

Fehonda Thermal Pad have two series of products: general Thermal Pad (B60 series) and low-volatile Thermal Pad (B50 series), and the materials can be customized according to the usage scenario.

When using thermal pad, in order to achieve the best effect, the surface of the component should be kept clean, free of grease and impurities. When using, remove the thermal pad protective film, then stick it on the surface of the heating element, and apply a certain amount of pressure to ensure that the thermal pad is in full contact with the radiator or shell, so as to achieve the best effect.

Features and Advantages

Thermal conductivity of Fehonda thermal pad: 1.5-10.0W/mk

Low thermal resistance, excellent thermal conductivity, strong weather resistance

Self-adhesive, good fit, easy to assemble

Soft, good compressibility, high reliability in long-term use

UL94 V-0 flame retardant, meets RoHS environmental protection requirements

Customization information

Available specifications: sheet, sliced, punched

Thickness: 0.3-10mm (thickness can be customized, such as: 0.75/1.1/1.25mm, etc.)

Standard size: 200*400mm (customizable die-cut size and shape)

Color: gray, blue, pink, etc. (can be customized according to customer requirements)

Hardness: Shore C 15-45, special hardness can be customized

Application

Applied between semiconductors and radiators or casings of products such as communication equipment, network terminals, LED lighting, 3C electronics, new energy vehicles, and high-power power supplies.

< Application of Thermal Conductive Silicone Film for CPU Heat Sink >

< Application of LED Thermal Conductive Silicon Film >

< Application of Thermal Conductive Silicone Film for Battery Pack >

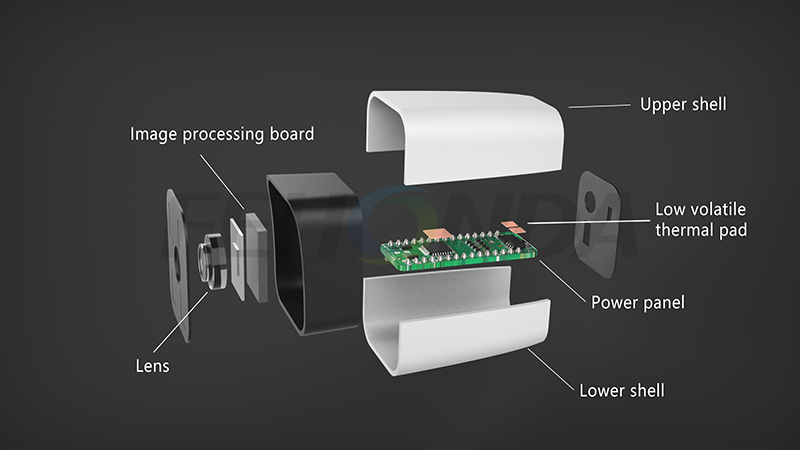

< Application of Thermal Conductive Silicone Film in Monitoring Equipment >